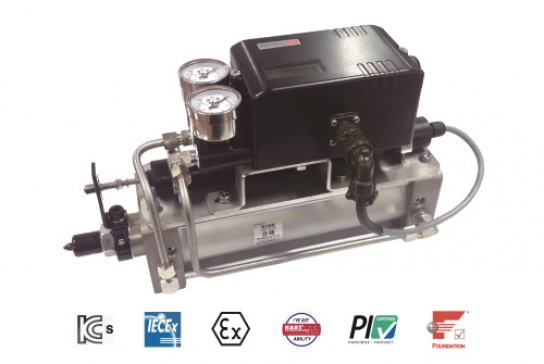

SS2C smart cylinder positioner

|

Description

Smart performance with innovative and ever-strong coil module even under harsh working environments

Main features

- Auto-calibration for optimum conditions

- Precise control performance and high dynamic response

- Easy operation with fork-key pads and full text graphical LCD

- Single and double acting

- Low air consumption due to piezo electric microvalve

- Pressure regulator built-in to eliminate variations in supply air pressure

- Problem-free characteristics on a small actuator

- High resistance against shock and vibration

- Mounting on rotary actuators according to VDI/VDE3845

Options

- Output position transmitter (4 - 20 mA)

- 2 x alarm limit or micro switch (SPDT)

- By-pass (Auto/Manual switch)

- Explosion proof type (Ex ia IIC T6)

- HART communication

- Profibus PA communication

- Foundation FF communication

Specifications

| Communication | Wthout | HART | Profibus PA | F. Fieldbus |

| Input signal/bus voltage | 4-20mA @ 24 VDC | 9 - 32 VDC | ||

| Min. / Max. Current | 3.6 mA / 50mA | - | ||

| Current Consumption | 15 mA | 16 mA | ||

| Voltage Drop (Res.) | 8.7 VDC (435Ω @ 20mA) | 9.4 VDC (470Ω @ 20mA) | - | - |

| Stroke / Angle | Linear type : 8 - 130mm | Rotary type : 25 - 120° | |||

| Air Supply Pressure | 1.4 - 7.0 bar (20 - 100 psi) | |||

| Output Pressure Range | 0 - 100% of supply air pressure | |||

| Air Capacity | 80 ℓ/min = 4.8 Nm3/h = 2.8 scfm (Sup = 1.4 bar) | 233 ℓ/min = 14 Nm3/h = 8.2 scfm | |||

| Air Consumption | 2.8 ℓ/min = 0.17 Nm3/h = 0.1 scfm (Sup = 1.4 ~ 6 bar) | |||

| Linearity | < ±0.3% F.S | |||

| Sensitivity | < 0.2% F.S | |||

| Hysteresis | < 0.2% F.S | |||

| Repeatability | < 0.2% F.S | |||

| LCD Indicator | 4-digit LCD indicator | |||

| Adjustable Speed | 1 - 1000 (lowest 1, highest 1000) | |||

| Scan Time | 2ms | |||

| Shut-off Value | Range 0 ~10% of position signal | |||

| Valve Action | Direct action(DA) / reverse action(RA) | |||

| Operating Temperature | -40 ~ +80℃ | |||

| Pneumatic Connections | PT 1/4, NPT 1/4 | |||

| Electrical Connections | PT 1/2, NPT 1/2, M20 x 1.5 | |||

| Protection Class | IP66 | Intrinsically safe (Ex ia IIC T6/T5) | T6 : -40 ~ +40℃ | T5 : -40 ~ +80℃ | |||

| Body Material | Aluminum die-cast / powder-painted | |||

| Weight | According to cylinder size and configuration | |||

How to order ...

| SS | - | A | B | C | D | F | G | H | I | J | K | L |

|

|

||||||||||||

|

|

|

A - Positioner type

|

||||||||||

|

|

|

[2] - SS2 smart cylinder positioner

[3] - SS3 smart explosion proof cylinder positioner

[5] - SS5 smart fail freeze cylinder positioner

|

||||||||||

|

|

|

B - Feedback sensor / lever

|

||||||||||

|

|

|

[C] - Linear sensor

[M] - Mechanical cam

|

||||||||||

|

|

|

C - Protection class

|

||||||||||

|

|

SS2/SS5

[I] - Intrinsic safe ATEX/IECEx - Ex ia IIC T6/T5 (Only M type)

[K] - Intrinsic safe KTL - Ex ia IIC T6/T5 (Only M type)

[W] - Standard IP66

SS3

[F] - Explosion-proof ATEX/IECEx - Ex d IIC T6/T5 (Only M type)

[K] - Explosion-proof KTL - Ex d IIC T6/T5 (Only M type)

|

|||||||||||

|

D - Cylinder stroke

|

||||||||||||

|

[0050] - 50 mm

...

[1000] - 1000 mm

Other on request

|

||||||||||||

|

F - Cylinder type

|

||||||||||||

|

[P] - ISO 15552 aluminium profil type

[T] - ISO 15552 Tie rods type

[S] - Tie rods compact type

|

||||||||||||

|

G - Bore size

|

||||||||||||

|

[050] - DN50

...

[320] - DN320

|

||||||||||||

|

H - Gauge block

|

||||||||||||

|

[N] - Sans

[1] - 6 bar

[2] - 10 bar

|

||||||||||||

|

I - Bypass

|

||||||||||||

|

[N] : None

[Y] : Included (Auto/Manual screw for SS2/SS3 only)

|

||||||||||||

|

J - Position feedback

|

||||||||||||

|

[N] - None

[O] - 4-20 mA

[S] - 2 x microswitch (SPDT)

[M] - 2 alarms + 4-20 mA

[Q] - 2 x microswitch (SPDT) + 4-20 mA

|

||||||||||||

|

K - Communication

|

||||||||||||

|

[N] - None

[H] - HART

[P] - Profibus PA

[F] - Fieldbus FF

|

||||||||||||

|

L - Fail position

|

||||||||||||

|

[N] - None

[O] - Open

[C] - Close

[F1] - Freeze on failure (fixe pres. @ 2.4 bar)

[F2] - Freeze on failure (pres. adjustable)

|

||||||||||||

| SS | - | A | B | C | D | F | G | H | I | J | K | L |

Code example

| Code example description : SS2C-W 0 4 0 0 S 2 0 0 2 Y N H F 2 |

|

Product : [SS2C] - SS2 smart cylinder positioner

Feedback sensor / lever : [C] - Linear sensor

Protection class : [W] - Standard IP66

Cylinder stroke : [0400] - 400 mm

Gauge block : [2] - 10 bar

Cylinder type : [S] - Tie rods compact type

Bore size : [200] - DN200

Gauge block : [2] - 10 bar

By-pass : [Y] - Included (Automatic/Manual screw)

Position feedback : [N] : None

Communication : [H] : HART

Fail position : [F2] - Freeze on failure (pres. adjustable)

|